Emerging Automotive Switch Applications

By Jérôme Smolinski & Regis Clement | August 02, 2021

Introduction:

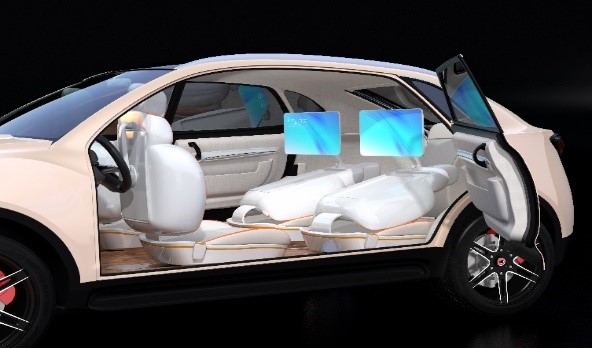

The development of artificial intelligence (AI) for autonomous vehicles is changing the rider experience. Fully-autonomous vehicles will lead to a complete overhaul of the vehicle cockpit. In fact, we have already seen major changes in cockpits that feature semi-autonomous capability. Functionality and comfort are primary factors driving the transformation of the automotive interior. Taking into account the increasing number of functions in the vehicles, designers and engineers must devote time to optimize the user interfaces between the driver and their new environment.

As the gateway to a user interface, a switch solution must have a desirable appearance, haptic feel and sound. The look, feel and method for interface interaction is one way vehicle manufacturers separate themselves from competing automakers. To achieve this result, switch manufactures work closely with automotive makers to optimize aesthetics, ergonomics and performance.

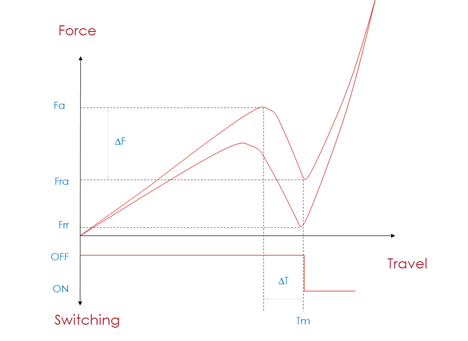

Haptics are directly linked to the switches mechanical features and is a combination of:

- Actuation force (Fa)

- Actuation return force (Fra)

- Tactile effect (Fa-Fra = ΔF) often voiced in % (ΔF/Fa = Δ%)

- Mechanical travel (Tm)

- Return force (Frr)

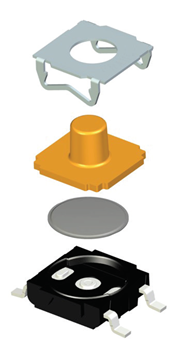

Switch manufacturers, like C&K, can adapt or change the components and parameters to create a unique haptic experience that defines an OEM product. From short-travel products with a strong click and loud noise, to a long-travel product with silent actuation, customization is the hallmark of today’s vehicles.

Automotive OEMs are focusing more and more on sound responses and consider the acoustic response as part of their branding. The audible response is highly dependent on the switch design, and vehicle manufacturers need to get the same sound response for all units, regardless of the switch configuration. The actuation sound, typically categorized as inaudible, soft, low, “metallic” or loud, can be controlled by the internal design, the mechanical properties, and the materials used.

In order to provide solutions that deliver repeatable audible responses, switch manufacturers have established platforms that allow designs to carry over to different applications. This unique offer provides high-reliability and consistent haptics by an automotive proven series, while also achieving drastically reduced development cost and time.

OEMs are approaching electromechanical component manufacturers for more than just the switch. By utilizing a switch manufacturer for designs beyond the switch itself, increased flexibility in design can be realized. Switch dimensions are becoming more critical, making it imperative to work closely with customers to discern all details. Today, it is less about the switch being mounted to a PC board or adding wire leads or a connector to the switch, and more about defining the functionalities that need to be added or design challenges that need to be solved. Because switch manufacturers are now dealing with the entire module, they are spending an increasing amount of time with customers to determine how the module is being impacted in the application to assess potential challenges that were not previously considered.

Emerging Application Examples

Security and Safety

The automotive market is experiencing a significant technological renaissance. The introduction of AI and driverless vehicles will change the way drivers and passengers interact in the vehicle. Driverless cars will lead a complete overhaul of the vehicle cockpit. In fact, we have already seen major changes in cockpits that feature semi-autonomous capability. Functionality and comfort are primary factors driving the transformation of the automotive interior.

Amongst other elements within the cockpit, seats are becoming more than just the place you sit to drive, or not drive. The quest for light weight solutions in automotive interiors is affecting the seats, but not to the detriment of the functions added to it:

- Position and Lumbar controls: traditional seat user settings and seat motors management including seat adjustment/movement, memory, lumbar control, heating, ventilation and massage

- Comfort detection: ability to detect seat element position

Two major trends derived from AI are an increase for miniature detect/snap switches in the seats. Previously, where an application relied on the availability of miniature tactile technology, the same application can now be better served by smaller, more flexible detect switch designs. In neighborhood electric vehicles (NEVs), the structure has changed to a full flat floor. It allows a re-arrangement of the interior, with configurations like business class seats for passengers. In these configurations, the systems need to know whether the seat is in its upright position, in relax or cargo mode in order to activate/deactivate security and safety systems like airbags.

Gaming

Infotainment systems will reign supreme in autonomous vehicles. And more specifically, gaming. Major vehicle manufacturers are already working on incorporating gaming capabilities directly into the functionality of vehicle. One example is using the gear shifter paddles and the steering wheel as gaming controls when the vehicle is in park. Detection switches are required to confirm the vehicle is in park, and gaming functionality can be employed. Multiuse detect switches are also required in the shifting paddles, as dual functionality is implemented for shifting gears in real-life and virtually.

The appeal of employing detect switches as opposed to alternative switch technologies like pushbuttons, snap-acting and slide switches, is that they are smaller and more flexible by design. The flexibility of detect switches is paramount to meeting the many requirements of automotive application. One such example is the angles with which a switch is capable of operating and subsequently detecting. Because many custom detect switches involve custom tooled contacts, these devices can be tailored to meet any number of vehicle detect requirements. In addition to miniaturization and versatility, detect switches also offer higher reliability. In fact, detect switches have been implanted into the high actuation consumer market, including traditional gaming devices. Gaming devices employ such switches to detect the presence of the game card.

Many vehicles utilize rotary switches to navigate through infotainment selections. Operated by rotating the switch dial, multiuse rotary switches can stop in different positions to control different circuits with a single switch. Rotary switches can also be designed to have many contacts happening at once on a single switch position. Rotary switches have a rotating spindle that can be customized to deliver precise tactile and audible feedback while rotating. Depending on the number of rotors, the switch can have dozens of different positions and each one can be attached to a particular circuit.

Joysticks

Multifunction control is a way of the future. Adaptive joysticks will be integrated into vehicles to offer more sophisticated vehicle control. Today’s vehicles already offer a combo automatic / manual gear shift with the slide of the joystick control. Gaming functionality can be added to a multi-function grips that combine bi-directional snap-acting switch models with a single switch function in both directions or a double function in both directions. These rugged, already available on off-road type vehicles, provide superior tactile feedback and positive snap-point action.

Joystick controls require an electromechanical device with an extremely reliable and repeatable switch mechanism. It is critical for the switch’s operating position to be consistent over time, and switch manufacturers are accomplishing this with calibrated snap-acting switches to ensure accuracy and reliability. The design of a snap-acting switch inherently features a precise actuator position for the entirety of the devices’ operating life, a characteristic not necessarily true of other mechanisms. This ensures a redundant and consistent engagement of a joystick or navigational control mechanism, providing smooth and accurate control for the operator, regardless of the speed of actuation. In addition, snap-acting switches, like C&K’s TFS Series, improve reliability. Snap-acting feature a robust design and high-life expectancy required in off-highway applications, as they can be rated up to IP67 with an operating life of up to 300,000 cycles.

With variations from surface mount and through-hole, to snap-in and snap-acting, lever actuation and over-travel detect switches are being customized to meet any criteria, making them suitable for automotive joysticks.

Conclusion

Automotive interface designs aim to simplify and enhance the user experience. Electromechanical switches are integral to defining the touch, feel and sound of interface actuation. With the evolution of autonomous automotive technology, the modern vehicle cabin features customized electromechanical switches that maximize functionality and optimize comfort, safety, infotainment and more. Customized for specific vehicles and manufacturers, advanced switching for these emerging in-cabin applications are often accomplished through sophisticated switch configurations. Autonomous vehicles will offer more bells and whistles than ever before, and electromechanical switches must enable multifunctionality to simplify design and integration while improving the user experience.